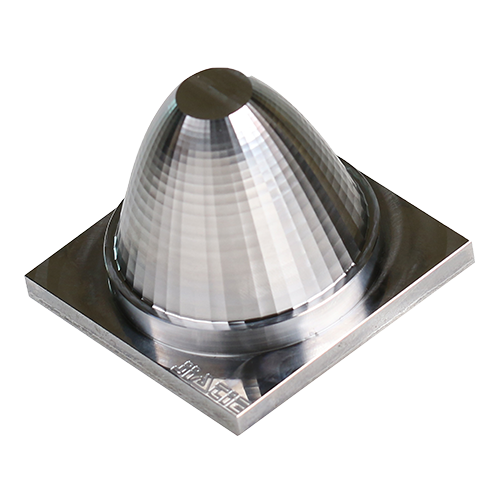

Cosmetic Milling Precision Mold, Electrode Guiding Solution

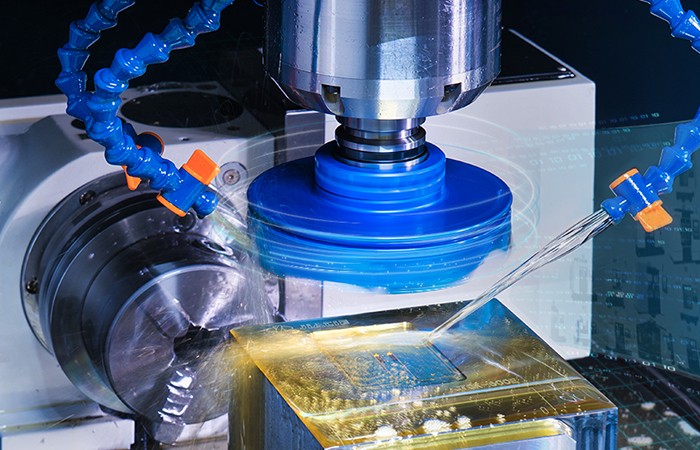

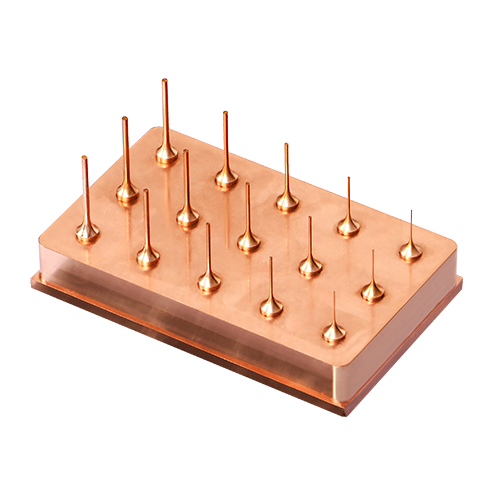

Application area: Machining of high surface requirement industries such as automotive, electrode, accurate mold, etc

Machining material: copper, aluminum, steel, stainless steel, etc

Language

Cosmetic Milling Precision Mold, Electrode Guiding Solution

Application area: Machining of high surface requirement industries such as automotive, electrode, accurate mold, etc

Machining material: copper, aluminum, steel, stainless steel, etc

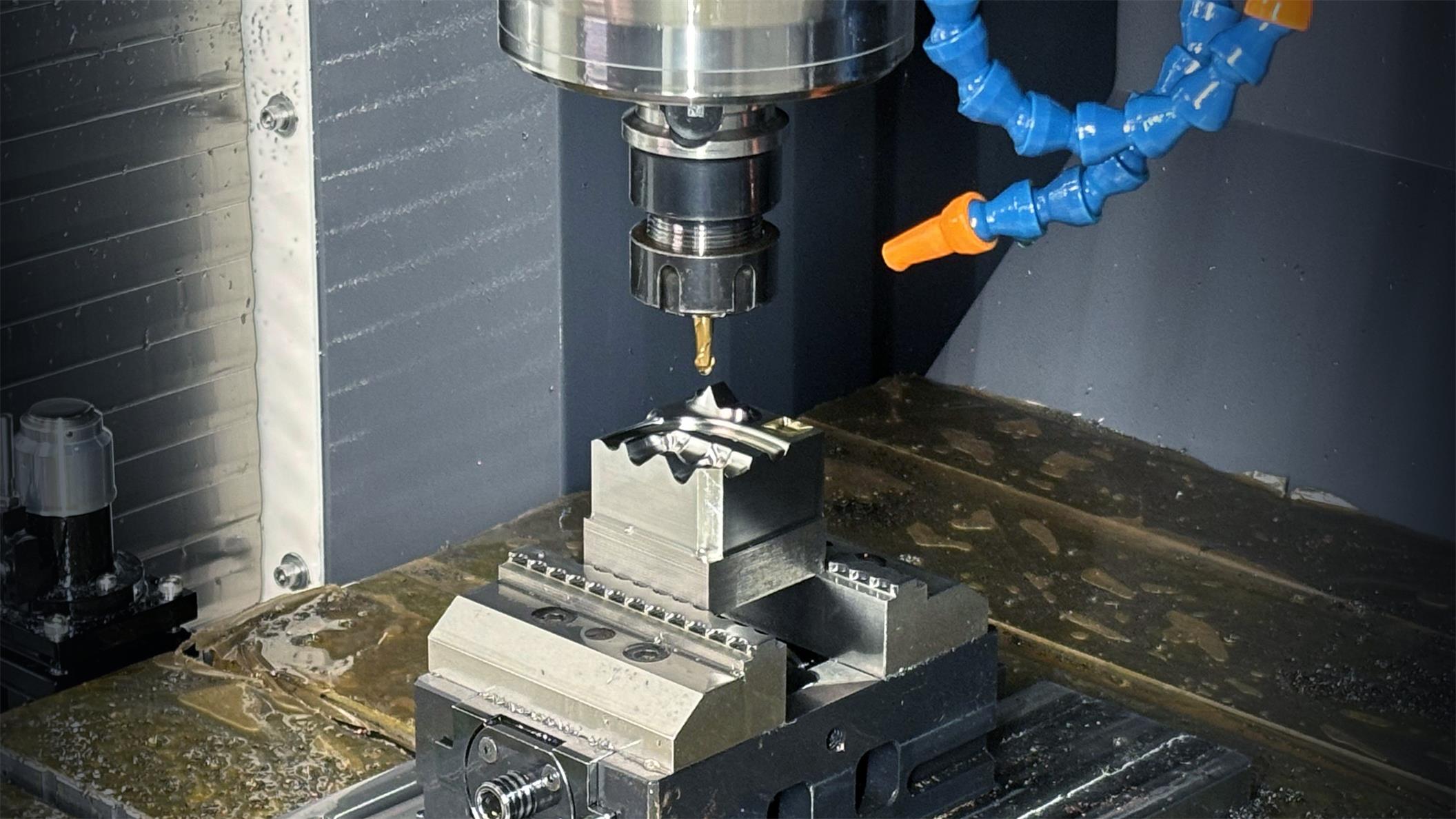

Brand new machine structure design, performance is more stable and reliable, high accuracy, fast speed and high rigidity.

High-speed and high-accuracy spindle makes the milling machining performance especially outstanding.

Box type Z axis structure, better dynamic performance.

High-end all-in-one outer looking design, operation and management are more humanized, less floor area and humanized operation interface.

Servo type fast tool magazine, fast tool change, reliable.

| Items | Technical Parameter |

| X/Y/Z travel | 500/600/300 mm |

| Work table dimension | 500×650 mm |

| Max workpiece height | 240mm(Low column) 340mm(High column) |

| Max load of worktable | 300kg |

| Machine net dimension | 2150 x 2150 x 2430mm (Chain type tool magazine) 1970 x 2150 x 2430mm (Circular type tool magazine) |

| Machine net weight | 3300kg |

| Click for details in PDF | Specification Download |

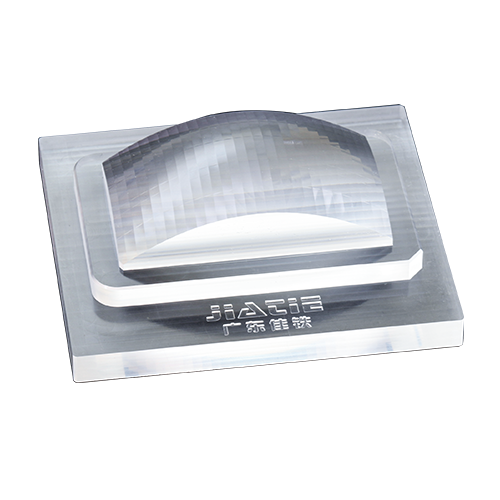

Cosmetic Milling Precision Mold, Electrode Guiding Solution

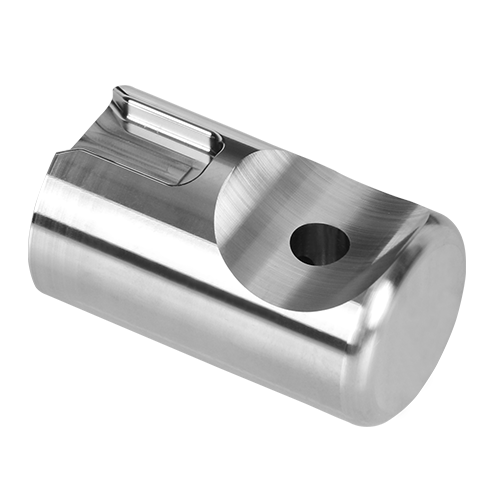

Application area: Machining of high surface requirement industries suchas automotive, electrode, accurate mold, etc

Machining material: Carbon steel, alloy steel, high-temperature alloy, alloy aluminum, copper, etc

Cosmetic Milling Precision Mold, Electrode Guiding Solution

Application area: Machining of high surface requirement industries suchas automotive, electrode, accurate mold, etc

Machining material: copper, aluminum, steel, stainless steel, etc

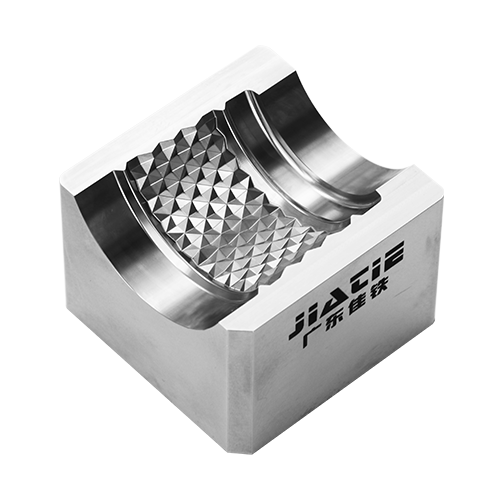

Economical and practical machine

Application area: accurate mold, electrode, electronic product, automotive, aviation and aerospace, shoe manufacturing, spectacle, etc.

Machining material: copper, aluminum, aluminum alloy, carbon steel, steel alloy and partial non-metal material

Cosmetic Milling Precision Mold, Electrode Guiding Solution

Application area: Machining of high surface requirement industries such as automotive, electrode, accurate mold, etc

Machining material: copper, aluminum, steel, stainless steel, etc

Regardless of whether you require general advice or specific support, we are happy to help you.