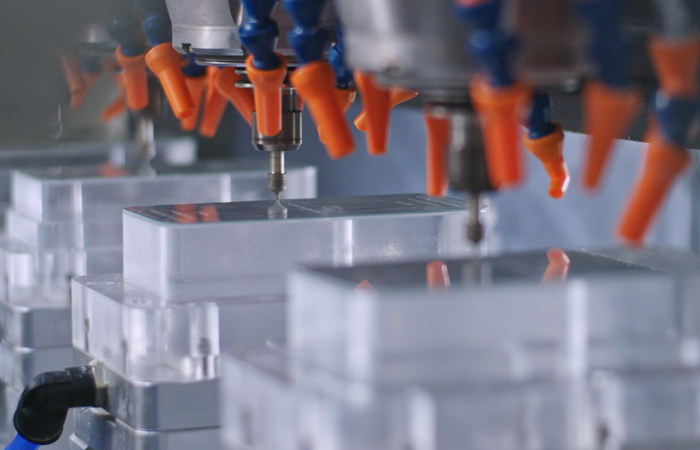

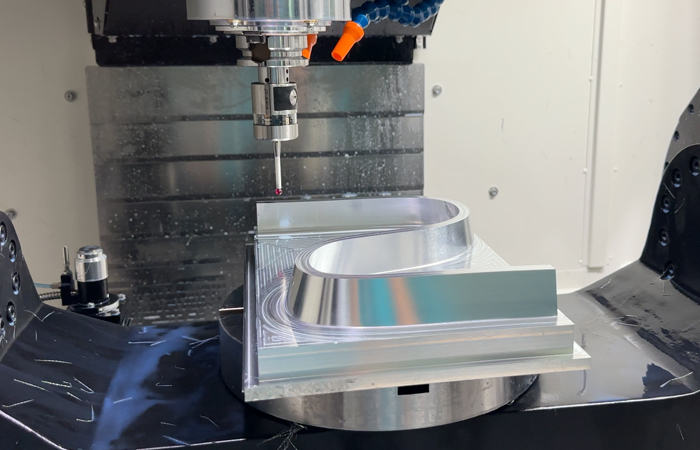

Equipped with the CNC system independently developed by Kejie technology, it has excellent motion control ability, high speed, high accuracy, high efficiency, and supports high-precision RTCP five-axis linkage processing and multi-axis, multi-channel control.

High-performance chips provide industry-leading processing speeds. The number of pre-read lines is 4096, the processing speed is 0.3ms, and the minimum program resolution is 0.00001. it provides the strongest performance guarantee for precision contours, 3D surfaces, and multi-axis interpolation.