The brand ‘JIATIE’ of KEJIE TECHNOLOGY CO., LTD. (hereinafter referred to as KEJIE TECHNOLOGY) was founded in 1998. For more than 20 years, the company adhere to the motto ‘good and dependable quality as iron’ as the original entrepreneurial spirit, cohesion to the managing policy of ‘leading technology, scientific management, continuous improvement, customer satisfaction’, focusing on equipment manufacturing industry, with the capability to research and develop, production and sales service. Today, KEJIE TECHNOLOGY has developed into a high-tech enterprise with nearly 1,000 employees, a leading member of drafting the PRC National Standard of ‘High-speed CNC Machining Center’ and awarded as the single-field champion enterprise in Guangdong Province manufacturing industry, also recognized as a National Intellectual Property Advantageous Enterprise in 2023.

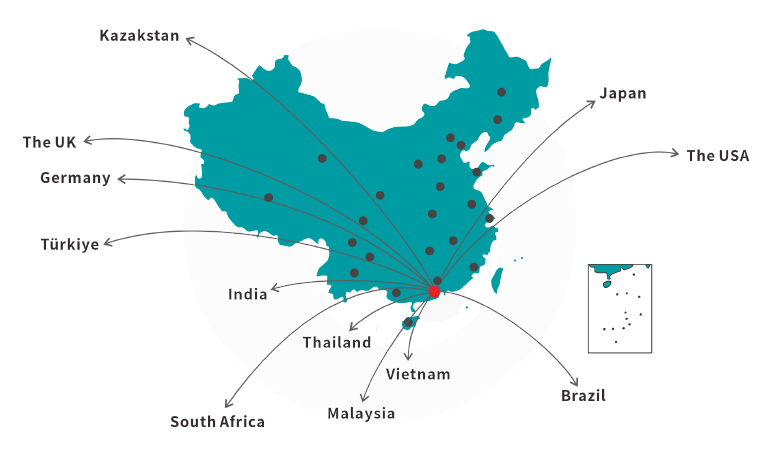

At present, the company has two core brands: “JIATIE” and “KEJIE”. Products are widely used in different industries such as electronics, medical instruments, automotive railway transportation, equipment manufacturing, molding industry, etc.The product includes CNC grinding center, CNC high-speed machines, 5-axis high-speed machine, vertical machining center, bonding machines, FPC soft-board laser cutting machines, automate production lines, establishing data center, etc. Among them, ‘High-speed CNC machining center’ and "Drilling and milling center JTDM-540" are recognized as Guangdong Province famous high-tech products. The products are exported to the United States, Germany, Britain, Japan and other top industrial countries.

Adhering to the service tenet of "customer oriented, proactive response", Jiatie service network has covered more than 40 regions and cities in China, providing customers with comprehensive, responsive and technical-based solutions for advanced support. Currently, the company maintains close cooperative relationships with various Global top 500 and Technology top 100 companies to provide customized solutions, and to achieve a win-win situation between enterprise value and customer value.

KEJIE TECHNOLOGY will continue to make unremitting efforts to gain customers’ confidence and praise with leading technology, high-quality products and attentive service.

Kejie technology carries out strict inspection on various raw materials and assembly process of machine tools to ensure that it meets the technical requirements or meets the relevant national standards. Before each machine tool is shipped, professional quality inspectors carry out various performance tests, especially the use of precision testing instruments for strict machine tool accuracy testing.

Regardless of whether you require general advice or specific support, we are happy to help you.