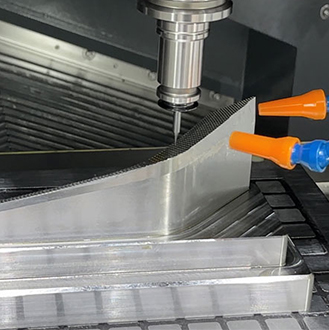

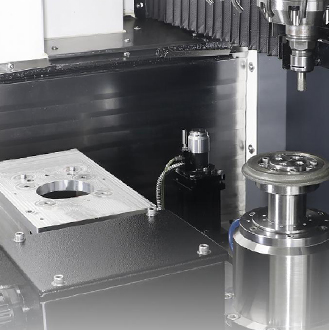

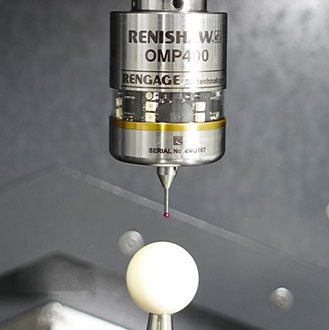

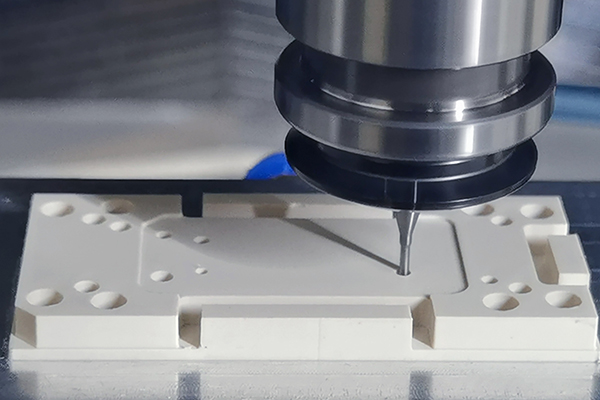

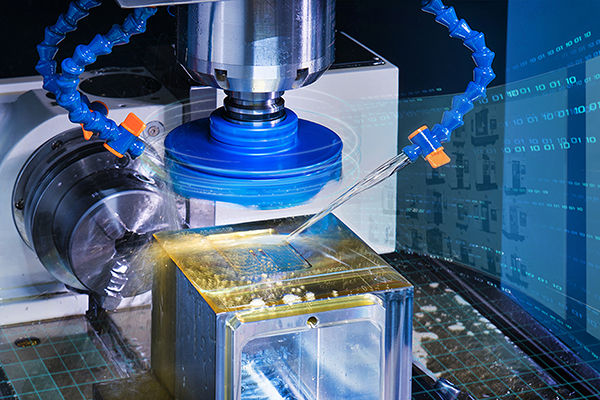

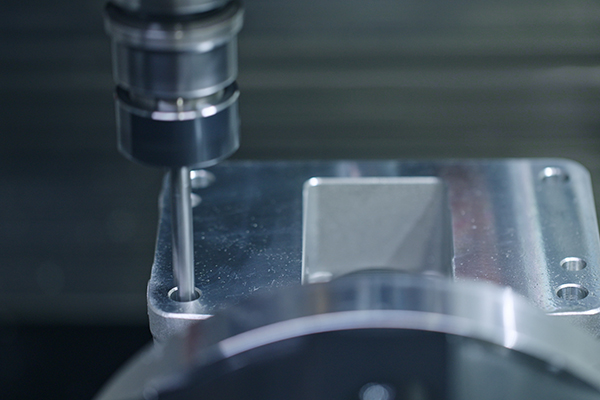

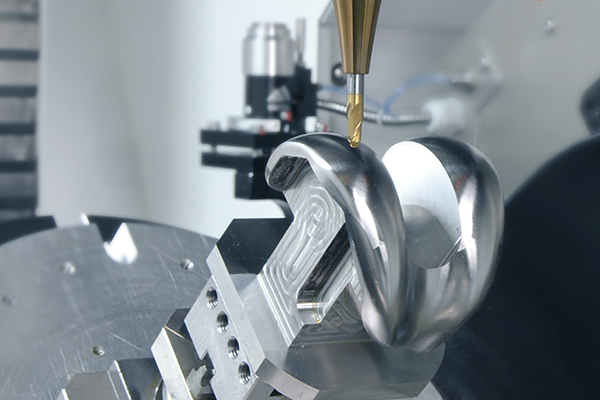

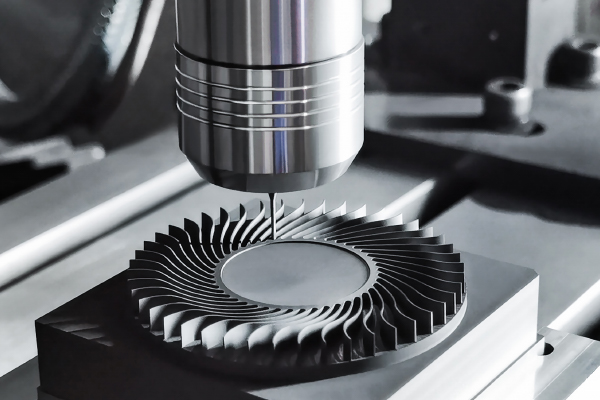

With JIATIE advanced spindle technology, high speed, high torque, high acceleration characteristics spindle is using for a variety of difficult machining materials, such as titanium alloy, superalloy, high hardness, hardening materials, it can achieve the rough and fine integrated processing at one clamping and maximize the yield.